Teach You How To Extend The Life Of A Hammer Crusher Head

Author:xixi Addtime:2018-07-26 Click:

Hammer crusher is the use of high-speed rotation of the hammer impact material, make the material along the natural fractures, bedding planes and other vulnerable part of the fracture and joint broken machine, widely used in mining, metallurgy, building materials and electric power industry. Hammer crusher in the process, due to the impact of the material and the friction is inevitable the hammer, liner, grate and other parts wear and failure, the head is easy wear parts mainly, its consumption is great, need to reserve a large number of spare parts, which not only occupied capital, and affect the normal production of enterprises. How to use the hammer crusher to improve service life?

Correct use and scientific maintenance of the device is always in good condition, effective way to prolong the service life of the hammer. If improper use and maintenance, not only easy to cause equipment failures, such as vibration, noise, heat, wear, and is bound to lead to the service life of the hammer is lower. Hammer crusher should pay special attention to the following points in the daily use and maintenance:

1) according to the design model, the proper control of feed size, strictly beyond the design of the maximum size of the material, man-machine

2) choose the appropriate feeding equipment, such as feeding by plate feeder or vibrating feeder, to ensure uniform and stable feeding, and avoid the impact of the uneven feeding on the equipment and ineffective operation

3) due to the quality of the hammer casting error, the use of hammer in the process should be in accordance with the current situation, on time inverted eye, flip, so that the hammer uniform wear and rotor balancing

4) when changing the new hammerhead, it is best to weigh, divided into several groups according to the average quality, the quality requirements of each group are equal, otherwise the rotor is unbalanced when it is switched on, and it is easy to cause vibration

5) when parking to check between the hammer and the sieve, sieve and sieve the gap between, and adjust if necessary, and regular replacement of the sieve. Because of high cost than the hammer sieve, sieve and sieve the new old compared with 4 - to hammer 5 classes.

6) hammer crusher hammer frame is made of cast steel, less contact with the material, but when the crusher into metal or lining off, easy to cause the hammer disc broken or bent, then should promptly be replaced, otherwise easy to lose hammer cause vibration.

7) the side hammer disk and the shell side of the hammer frame are impacted by the material, and the wear of the side hammer disk is serious. In order to prolong the service life of the side disk, the wear-resistant layer can be deposited on the circumferential surface of the side plate and the side of the side plate

8) because of the friction in the running, the spindle shaft diameter at both ends is easy to wear. When installing, two shaft sleeves are added to the axle diameter, so that it is wrapped on the shaft to protect the axle diameter

9) the bearing should be repaired and adjusted in time after the wear of the bearings. The bearings should be scraped and adjusted according to the new size, and the thickness of the gasket should be adjusted so as to keep a reasonable gap so as to form an effective lubricating film

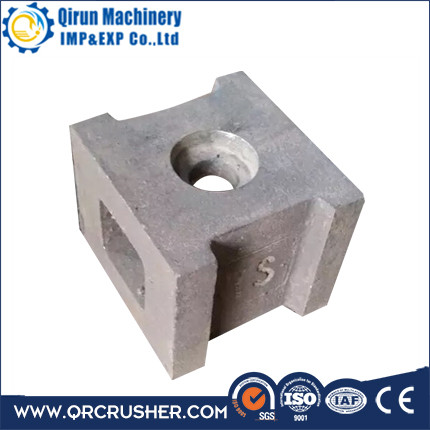

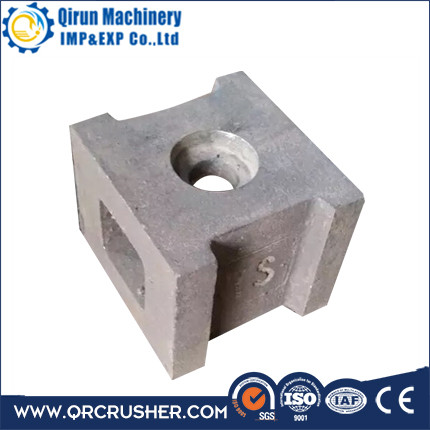

Shuangfeng Qirun Machinery Parts IMP&EXP Co.,Ltd, specializing in the production of domestic and foreign brands of crusher wear spare parts manufacturers, production of domestic brands, Hua Yang, Shan Bao, SBM brands such as crusher wear parts, spare parts, as well as foreign brands, common, Sandvick, TEREX and other import brands crusher spare parts, wear parts, mining quarry companies such as crusher wear parts of choice. We achieve cost-effective localization of imported spare parts, service users at home and abroad. The company can be matched with various brands of hydraulic crusher electric parts, sealing parts, standard parts and other accessories, can meet the needs of one-stop shopping for customers at home and abroad the demand.

Shuangfeng Qirun Machinery Parts IMP&EXP Co.,Ltd has thirty years of production experience, and years of experience in processing export products, products have been exported to the United States, Canada, Australia, Sweden, Finland, Russia, Ukraine and Southeast Asia and other countries and regions. Shuangfeng Qirun Machinery Parts IMP&EXP Co.,Ltd product using the original material, high-quality raw materials, casting and heat treatment process we have a unique thirty years production experience, to ensure complete interchangeability, and original spare parts with high quality and competitive price, provide quality products, quality services for the majority of users.

Shuangfeng Qirun Machinery Parts IMP&EXP Co.,Ltd wearable parts can be customized to map, and if there is no map, the company has professional mapping personnel to help you mapping, after customization

Contact:Sales Director: Eileen Cai ;

Email: sales@qrcrusher.com;

Mobile telephone: +8618973821771