Method For Replacing Lining Board Of HP500 Crusher

Author:xixi Addtime:2018-07-27 Click:

HP500 crusher is one of the core equipment factory workshop production, its performance directly affects the efficiency of the company's benefit. So the crushing machine daily maintenance and maintenance is very important, now the main maintenance project to replace the crusher liner process to do a detailed description:

1, notify the dispatch of power failure, the electrician for power failure procedures;

2, confirm that the crusher is out of power, the operation box is repaired and the maintenance plate is correctly hoisted;

3, the lubrication pump unloading treatment;

4, the ore belt pull rope switch pull, clean the belt head, pumice;

5, remove the material, cover, pan, cover plate, fixed cone, dust cover and other four big pieces. During the lifting process, the crane shall be directed by special personnel and strictly abide by the operation rules of lifting operation;

6, split tray: clean up the lining plate bolt of slag, remove lock bolts, remove after blanking disc check and confirm whether to continue to use, such as the need to change immediately obtain a new lining plate. The use of hammer and hammer hammer grip hand shall not wear gloves and wear goggles with care personnel;

7, remove the cone: check the size of the ring gear (wheel) occlusion, start the hydraulic motor rotation gear ring. The process requires special care. When the cone is completely removed, lifted to the designated location;

8, remove the lifting cone: the process should have a special command of crane, hanging out of the process to slow, steady, in case of knocking the hammer cone copper bearing;

9, check the balance, the base plate, bearing, horizontal shaft (retaining plate) and related components; if the parts need to be replaced and maintained, they should be reported to the leader for related treatment immediately;

10, lifting the fixed cone of new rings and wire rope should meet the bearing requirements, carefully cleaning the cone shaft root stains, lifting fall slowly to be placed to the eccentric shaft, and a personal care in command, the moving cone and the eccentric shaft is combined and is not fully in place should stop falling, this should contact scheduling open lubrication pump for 1~2 minutes, then fall cone in place;

11, the new fixed cone hoisting process must be carefully placed: slow down, carefully check the fixed cone and the gear slot is correct with the fixed cone thread start point and thread start point matrix is consistent, the above points are in line with the case, start the hydraulic motor, rotating cone to the discharge port in accordance with production requirements. This process also need special care, check the size of the gear fit;

12, installation of the lining plate: the lining plate positioning pin alignment into the moving cone lock nut hole, the locking bolt, with sixth items using a sledgehammer when;

13, cover the locking bolts on the distributor plate, and fill the broken ore for the next demolition;

14, hoisting, fixed cone, dust cover, cover plate, big pot, blanking port, protective cover, etc. four big pieces

Process notes are the same as those of the fifth;

15, the lubricating pump pressure valve to restore, check the pressure is in line with production requirements;

16, the belt pull rope reset, remove the repair card, the operating box switch to the automatic location, cleaning tools clean up the scene;

17, after the above matters have been dealt with, inform dispatch to carry on the electricity to the crusher

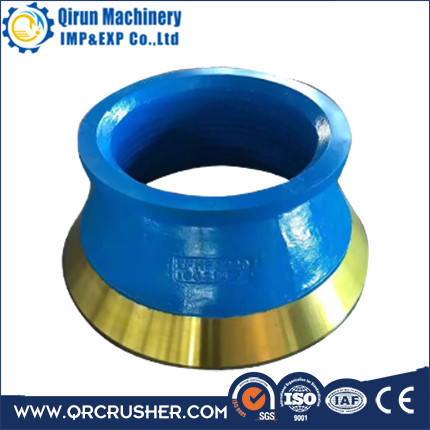

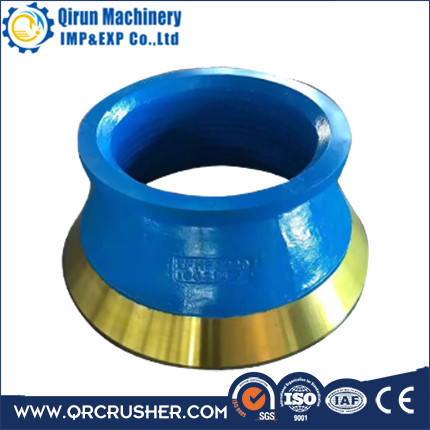

Shuangfeng Qirun Machinery Parts IMP&EXP Co.,Ltd, specializing in the production of domestic and foreign brands of crusher wear spare parts manufacturers, production of domestic brands, Hua Yang, Shan Bao, SBM brands such as crusher wear parts, spare parts, as well as foreign brands, common, Sandvick, TEREX and other import brands crusher spare parts, wear parts, mining quarry companies such as crusher wear parts of choice. We achieve cost-effective localization of imported spare parts, service users at home and abroad. The company can be matched with various brands of hydraulic crusher electric parts, sealing parts, standard parts and other accessories, can meet the needs of one-stop shopping for customers at home and abroad the demand.

Shuangfeng Qirun Machinery Parts IMP&EXP Co.,Ltd has thirty years of production experience, and years of experience in processing export products, products have been exported to the United States, Canada, Australia, Sweden, Finland, Russia, Ukraine and Southeast Asia and other countries and regions. Shuangfeng Qirun Machinery Parts IMP&EXP Co.,Ltd product using the original material, high-quality raw materials, casting and heat treatment process we have a unique thirty years production experience, to ensure complete interchangeability, and original spare parts with high quality and competitive price, provide quality products, quality services for the majority of users.

Shuangfeng Qirun Machinery Parts IMP&EXP Co.,Ltd wearable parts can be customized to map, and if there is no map, the company has professional mapping personnel to help you mapping, after customization

Contact:Sales Director: Eileen Cai ;

Email: sales@qrcrusher.com;

Mobile telephone: +8618973821771