Talking about roll crusher

Author:xixi Addtime:2018-07-27 Click:

I, Introduction to roll crusher

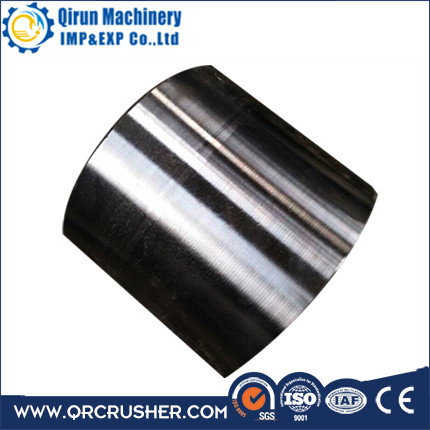

The roller crusher (twin roller crusher) mainly consists of roller, roller support bearing, compression and adjustment device and drive device and other parts

Hunan Fengwei Wear Parts Foundry of casting roller crusher accessories, such as equipment of grinding roller is equipped with a removable wear-resistant liner, selected high-quality raw materials, through the reasonable ratio of element (molybdenum, manganese, lanthanum etc.), forming a medium frequency melting furnace, and a heat treatment by column process (after heat treatment temperature reaches 1045 degrees) produced products of toughness and wear resistance can reach 1.2 to 1.5 times that of similar products. Has the advantages of long service life, easy damage, convenient maintenance and so on, this is any other type of domestic crusher are incomparable.

The roller crusher can not only widely used in cement, metallurgy, chemical, electric power, coal industry and so on the brittle and ductile materials processing,It can also be used in ore processing, chemical, cement, building materials and other industrial sectors, crushing and fine crushing of ores and rocks of medium hardness.

To roll crusher will be broken by feeding materials into the mouth two rolls, squeeze broken material fall naturally. In case of perfect or not can be broken when the crusher roller of the roller by hydraulic cylinder or the action of the spring automatically yield, increase the roll gap, too hard or not can be broken down, so as to protect the machine from being damaged. The two rollers rotate oppositely a certain gap, changing the gap, you can control the maximum discharge size. Double roll crusher is the use of a pair of opposite rotating round roll, four roll crusher is crushing operations by using two pairs of oppositely rotating round roller.

�

2,the main factors affecting roller skin wear are:

The hardness and particle size of the broken material, the material of the roll leather, the size and surface shape of the roller, the way of feeding, etc.

Material distribution as much as possible in order to reduce the roller surface of the ring groove and roll leather wear degree

In the operation of the crusher, especially in the process of coarse crushing, we should pay attention to the size of the ore block, prevent the ore block is too large, resulting in severe vibration of the crusher, so as to seriously wear the roll leather

Select the roller with good abrasion resistance, which can reduce the wear degree of roll leather, thus prolonging the service life of roller;

The length of the ore feeder shall be consistent with the length of the roller to ensure uniform feeding along the length of the roller. Moreover, in order to continue feeding the ore, the ore feeder shall be 1-3 times faster than the rod

(5) check the particle size of the crushing product frequently, and should move one of the rollers along the axial direction in a certain time. The moving distance is approximately equal to 1/3 of the particle size of the ore

In addition, but also pay attention to the roller lubrication, and the need to cover on the left in the security inspection hole, wear and easy to observe the skin.

Shuangfeng Qirun Machinery Parts IMP&EXP Co.,Ltd, specializing in the production of domestic and foreign brands of crusher wear spare parts manufacturers, production of domestic brands, Hua Yang, Shan Bao, SBM brands such as crusher wear parts, spare parts, as well as foreign brands, common, Sandvick, TEREX and other import brands crusher spare parts, wear parts, mining quarry companies such as crusher wear parts of choice. We achieve cost-effective localization of imported spare parts, service users at home and abroad. The company can be matched with various brands of hydraulic crusher electric parts, sealing parts, standard parts and other accessories, can meet the needs of one-stop shopping for customers at home and abroad the demand.

Shuangfeng Qirun Machinery Parts IMP&EXP Co.,Ltd has thirty years of production experience, and years of experience in processing export products, products have been exported to the United States, Canada, Australia, Sweden, Finland, Russia, Ukraine and Southeast Asia and other countries and regions. Shuangfeng Qirun Machinery Parts IMP&EXP Co.,Ltd product using the original material, high-quality raw materials, casting and heat treatment process we have a unique thirty years production experience, to ensure complete interchangeability, and original spare parts with high quality and competitive price, provide quality products, quality services for the majority of users.

Shuangfeng Qirun Machinery Parts IMP&EXP Co.,Ltd wearable parts can be customized to map, and if there is no map, the company has professional mapping personnel to help you mapping, after customization

Contact:Sales Director: Eileen Cai ;

Email: sales@qrcrusher.com;

Mobile telephone: +8618973821771